1. Site terms

By accessing Status Pro Maschinenmesstechnik GmbH web pages you agree to the following terms. If you do not agree to the following terms, please notice that you are not allowed to use the site.

2. Disclaimer

This site and the contents herein are provided as a convenience to you. The contents of Status Pro Maschinenmesstechnik GmbH web pages are provided on "as is" and "as available" basis. Status Pro Maschinenmesstechnik GmbH does not warrant that its Web pages will be uninterrupted or error-free. Status Pro Maschinenmesstechnik GmbH reserves the right to revise the pages or withdraw access to them at any time.

NO WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTIES OF TITLE OR NON-INFRINGEMENT OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, IS MADE IN RELATION TO THE AVAILABILITY, ACCURACY, RELIABILITY OR CONTENT OF THESE PAGES. STATUS PRO SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES, LOST PROFITS OR FOR BUSINESS INTERRUPTION ARISING OUT OF THE USE OF OR INABILITY TO USE THIS SERVICE, EVEN IF STATUS PRO INSTRUMENT HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SOME JURISDICTIONS DO NOT ALLOW EXCLUSION OF CERTAIN WARRANTIES OR LIMITATIONS OF LIABILITY, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. THE LIABILITY OF STATUS PRO WOULD IN SUCH CASE BE LIMITED TO THE GREATEST EXTENT PERMITTED BY LAW.

3. Copyright Information

The contents of Status Pro Maschinenmesstechnik GmbH www pages are Copyright © Status Pro Maschinenmesstechnik GmbH if not explicitly otherwise indicated. Any rights not expressly granted herein are reserved. Reproduction, transfer, distribution or storage of part or all of the contents in any form without the prior written permission of Status Pro Maschinenmesstechnik GmbH is prohibited except in accordance with the following terms. Status Pro consents to you browsing Status Pro pages on your computer or printing copies of extracts from these pages for your personal use only and not for redistribution unless consented to in writing by Status Pro. Individual documents in our web pages may be subject to additional terms indicated in those documents.

The use of this site and the content therein, is permitted to private, non-commercial use. The use of press releases and other documents classified as public is permitted in public communications if the source for the information has been stated.

4. Disclaimer

This site and the contents herein are provided as a convenience to you. The contents of Status Pro Maschinenmesstechnik GmbH World Wide Web pages are provided on "as is" and "as available" basis. Status Pro Maschinenmesstechnik GmbH does not warrant that its Web pages will be uninterrupted or error-free. Status Pro Maschinenmesstechnik GmbH reserves the right to revise the pages or withdraw access to them at any time. NO WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTIES OF TITLE OR NON-INFRINGEMENT OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, IS MADE IN RELATION TO THE AVAILABILITY, ACCURACY, RELIABILITY OR CONTENT OF THESE PAGES. STATUS PRO SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES, LOST PROFITS OR FOR BUSINESS INTERRUPTION ARISING OUT OF THE USE OF OR INABILITY TO USE THIS SERVICE, EVEN IF STATUS PRO INSTRUMENT HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SOME JURISDICTIONS DO NOT ALLOW EXCLUSION OF CERTAIN WARRANTIES OR LIMITATIONS OF LIABILITY, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. THE LIABILITY OF STATUS PRO WOULD IN SUCH CASE BE LIMITED TO THE GREATEST EXTENT PERMITTED BY LAW.

5.Third Party Web Sites and Information

For your easy accessibility Status Pro may include links to sites on the Internet that are owned or operated by third parties. By linking to such third-party site, you shall review and agree to that site’s rules of use before using such site. You also agree that Status Pro has no control over the content of that site and cannot assume any responsibility for material created or published by such third-party sites. In addition, a link to a non-Status Pro site does not imply that Status Pro endorses the site or the products or services referenced in such third party site.

6. Reviews, Comments, Communications And Others Content

By submitting material to any of our servers, for example, by e-mail or via the Status Pro Maschinenmesstechnik GmbH World Wide Web pages, you agree that: (a) the material will not contain any item that is unlawful or otherwise unfit for publication; (b) you will use reasonable efforts to scan and remove any viruses or other contaminating or destructive features before submitting any material; and (c) you own the material or have the unlimited right to provide it to us and Status Pro Maschinenmesstechnik GmbH may publish the material free of charge and/or incorporate it or any concepts described in it in our products without accountability or liability (d) you agree not to take action against us in relation to material that you submit and you agree to indemnify us if any third party takes action against us in relation to the material you submit.

7. Trademark Information

Status Pro is a registered trademark of Status Pro Maschinenmesstechnik GmbH. Other product and company names mentioned herein may be trademarks or trade names of their respective owners. Copyright © Status Pro Maschinenmesstechnik GmbH. All rights reserved.

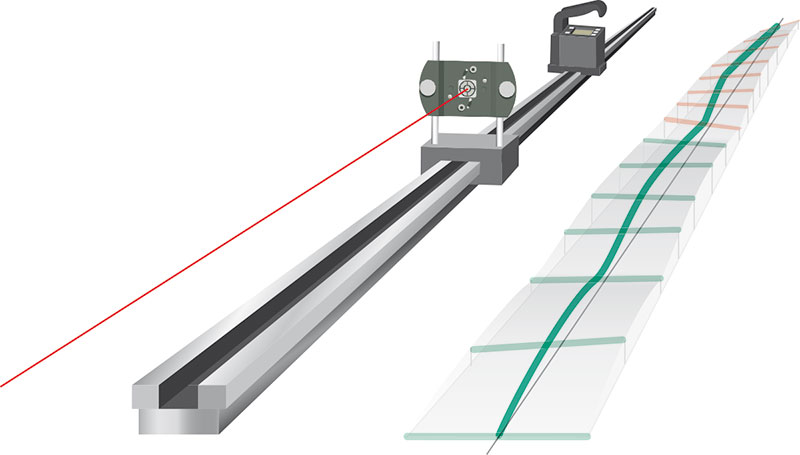

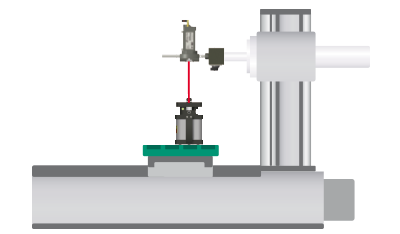

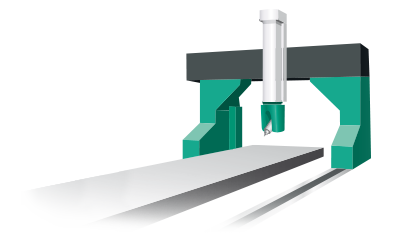

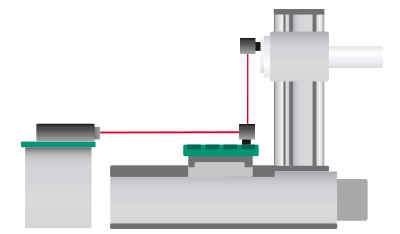

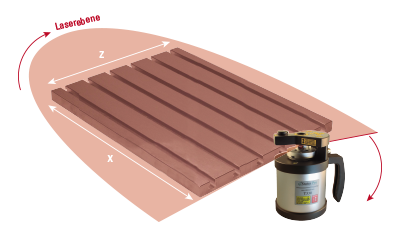

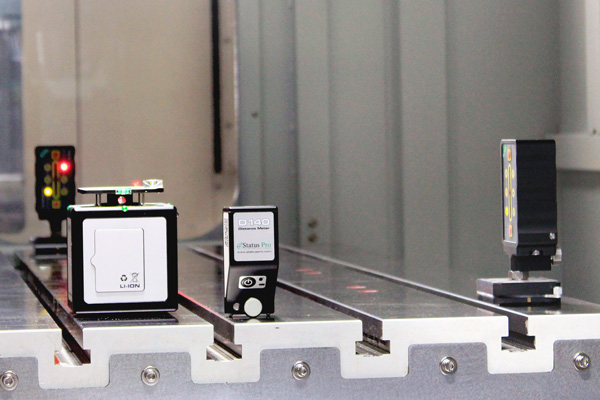

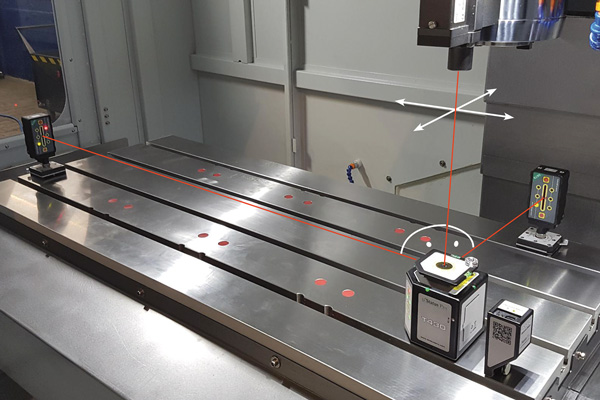

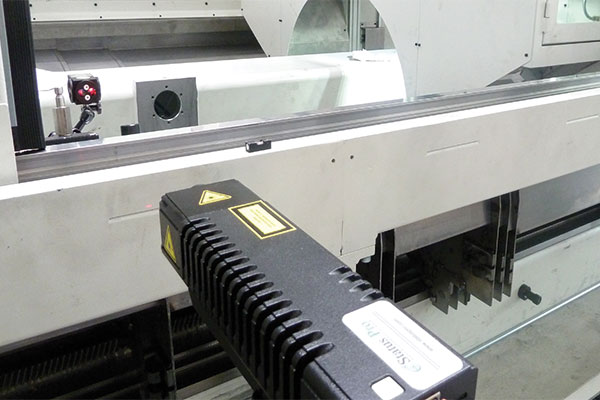

Measurement with µLevel

Measurement with µLevel

Design & Programming

Design & Programming